发布者: 中国重型机械工业协会 发布时间:2024-03-01阅读次数:654

世界之最科技成果:世界上公称挤压力最大(225MN)的铝挤压机

——2023年重型机械世界之最科技成果获奖项目专题报道

设备/技术名称:25MN卧式铝挤压成套装备关键技术研发及应用

研制单位:太原重工股份有限公司 www.tyhi.com.cn,太重(天津)滨海重型机械有限公司

首次投运时间:2017.11

联系人:王晓磊,17694972845

本项目属于工业制造领域有色金属成型行业的超大重型成套装备,其生产的铝合金型材被广泛应用于航空、航天、舰船、高铁等国防和重大新兴工业领域,尤其是薄壁、宽幅、高精度、截面复杂的超大规格铝合金型材,对上述领域的轻量化、高速化发展具有战略支撑作用。

本项目创新成果整体达到国际先进水平,其中大中型挤压机“叠板张力柱式全预紧封闭框架” 设计计算方法及制造安装技术达到了国际领先水平:首次提出双勾头、双半圆键传力结构和预张紧加工技术,张力柱应力高值降幅达70%,加工量减少90%,加工期缩短60%,突破了张力柱长期制约框架承载能力的瓶颈。

本项目共授权专利24项,推动了我国重型铝挤压加工装备研制水平的整体提升。项目产品累计销售4台套,首套“225MN卧式铝挤压成套装备”成功应用于辽宁忠旺铝挤压加工基地项目,经济和社会效益显著。为实现高端超大规格工业铝型国产化、服务重大战略产业的轻量化发展、提升中国高端装备的全球竞争力奠定了重要基础。

图1:225MN铝挤压成套装备由挤压机前设备、挤压机主机和成品后处理设备组成,挤压机前设备主要用于模具加热,坯锭加热、润滑、输送等;挤压机主机作为铝挤压成套装备的核心,负责完成制品的挤压成形;成品后处理设备主要用于对挤压制品进行淬火、牵引、横向转移、拉扭矫直及定尺锯切等。

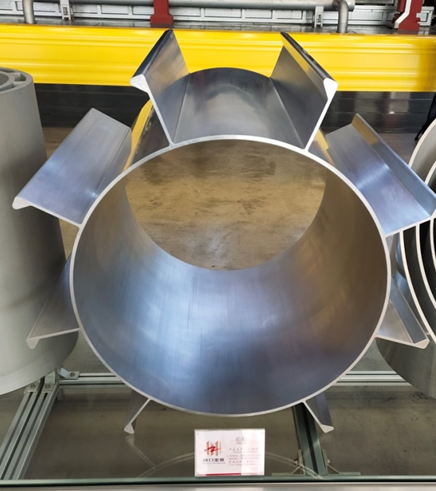

图2:225MN铝挤压生产线所挤压型材最大外接圆可达φ800mm,此图中挤制产品为电机外壳,合金6063-T6,主要应用于轻量化交通运输领域。

图3:传统冲锋舰船体采用耐海水腐蚀性好的5系铝型材拼焊而成,单件最大宽度约0.5m,焊缝较多,焊缝易受海水腐蚀,渗漏几率大,严重影响舰船使用安全性;采用225MN铝挤压机,通过先挤制带筋圆筒再切割宽展的方式,展幅可达1690mm,综合焊缝减少60%,降低了渗漏几率,极大提升了舰船的使用安全性和寿命。

The world's largest aluminum extrusion press in terms of nominal extrusion pressure

Research and Development on Key Technology and Its Application of The 225MN Horizontal Aluminum Extrusion Complete Equipment

Taiyuan Heavy Industry CO.,LTD, www.tyhi.com.cn

TZ(Tianjin)Binhai Heavy Machinery CO.,LTD

This project, the oversized and heavy sets of equipment, belongs to the non-ferrous metal forming industry in the field of industrial manufacturing, and the aluminum alloy profiles it produces are widely used in the fields of national defense and major emerging industries such as aviation, aerospace, ships, high-speed railways, etc. In particular, the oversized aluminum alloy profiles with thin-walled, wide-width, high-precision and complex cross-section are of strategic support to the development of the above fields in terms of lightweighting and high-speed development.

The innovative achievements of this project have reached the international advanced level as a whole, among which the design calculation method and manufacturing and installation technology of " Fully Pre-tensioned Closed Frame with Laminated Plate Tension Column" for large and medium-sized extrusion presses have reached the leading level in the world: it is the first time to put forward double hooks, double semi-circular key force transmitting structure and pre-tensioning processing technology, and the high value of the tension column stress has been reduced up to 70%, and the processing quantity has been reduced by 90%, the processing period has been shortened by 60%, and it breaks through the bottleneck of the long-time constraints on the frame load-bearing capacity of the tension column.

A total of 24 patents have been authorized for this project, which has promoted the overall improvement of the development level of heavy-duty aluminum extrusion equipment in China. Four sets of this project products have been sold, and the first set of "225MN horizontal aluminum extrusion equipment" has been successfully applied in Liaoning Zhongwang Aluminum Extrusion and Processing Base Project, with remarkable economic and social benefits. The project has laid an important foundation for realizing the localization of high-end oversized industrial aluminum, serving the lightweight development of major strategic industries, and enhancing the global competitiveness of China's high-end equipment.