发布者: 中国重型机械工业协会 发布时间:2025-03-24阅读次数:12

项目名称:500MW冲击式水轮机转轮轮毂及配套水斗锻件(runner and bucket forgings for 500MW impulse turbine )

研制单位:中国第一重型机械股份公司(China First Heavy Machinery Co., Ltd)

研制单位网址: https://www.cfhi.com/

首次投运时间:2023年11月

联系人:芮守泰,15022397190,ruishoutai@163.com

水轮机整体转轮由转轮轮毂和水斗两部分通过焊接组合而成。500MW转轮轮毂锻件采用了300吨级马氏体不锈钢钢锭,锻造毛坯重量超过150吨、外圆直径近5米、最大厚度约1.2米,成品轮毂锻件重量达到105吨,是目前世界最大规格的马氏体不锈钢转轮锻件,也是目前唯一的交货重量超百吨的水电不锈钢整体锻件。扎拉转轮模锻水斗锻件的毛坯重量超过3吨,壁厚跨度30至300毫米,斗宽约1.3米,锻件形状复杂系数达S4级以上,属于大型深腔复杂曲面马氏体不锈钢锻件,整体仿形锻造难度非常大。

转轮轮毂和水斗锻件的技术水平在一定程度上代表了500MW冲击式水轮发电机组的整体技术水平。500MW冲击式水轮机组是展现国家能源装备制造实力,再次用世界一流的水电技术问鼎世界水电之巅的一次重大机遇与挑战。将实现全产业链的完全自主知识产权国产化,大幅提高我国在巨型冲击式水电机组方面的研发、制造水平。

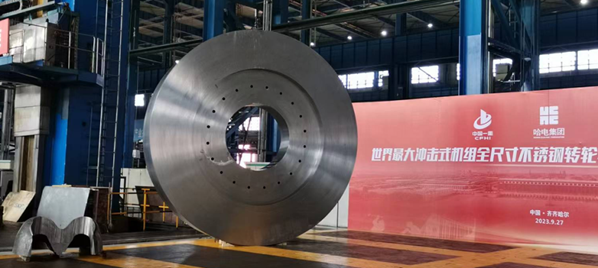

上图:世界最大冲击式机组全尺寸不锈钢转轮轮毂及水斗锻件完工仪式

左图:500MW水斗锻件 右图:500MW水斗锻件

THE RUNNER AND BUCKET FORGINGS FOR 500MW IMPULSE TURBINE IS THE WORLD'S LARGEST RUNNER AND BUCKET FORGINGS FOR IMPULSE TURBINE (WITH DIAMETER 4.72M, HEIGHT 1M, WEIGHT 270T).

The integral runner of a hydraulic turbine is composed of the runner hub and buckets through welding. The 500MW runner hub forging adopts a 300-ton martensitic stainless steel ingot. The forged blank of the 500MW runner hub weighs over 150 tons, with an outer diameter of nearly 5 meters and a maximum thickness of about 1.2 meters. The finished hub forging weighs 105 tons.It is currently the largest martensitic stainless steel runner forging in the world and also the only hydropower stainless steel integral forging with a delivery weight exceeding 100 tons. The blank weight of the die-forged bucket forging of the Zala runner exceeds 3 tons. The wall thickness span is from 30 to 300 millimeters, and the bucket width is about 1.3 meters. The forging shape complexity coefficient is above S4 level. It belongs to a large-scale deep-cavity complex curved surface martensitic stainless steel forging. The overall profile forging is extremely difficult.

To a certain extent, the technical level of runner hub and bucket forgings represents the overall technical level of 500MW impulse hydro-generator sets. The 500MW impulse hydro-generator set is a major opportunity and challenge to demonstrate the manufacturing strength of national energy equipment and once again reach the top of the world's hydropower with world-class hydropower technology. It will realize the localization of complete independent intellectual property rights of the whole industrial chain and greatly improve China's research and development and manufacturing level in giant impulse hydro-generator sets.