发布者: 中国重型机械工业协会 发布时间:2024-03-01阅读次数:226

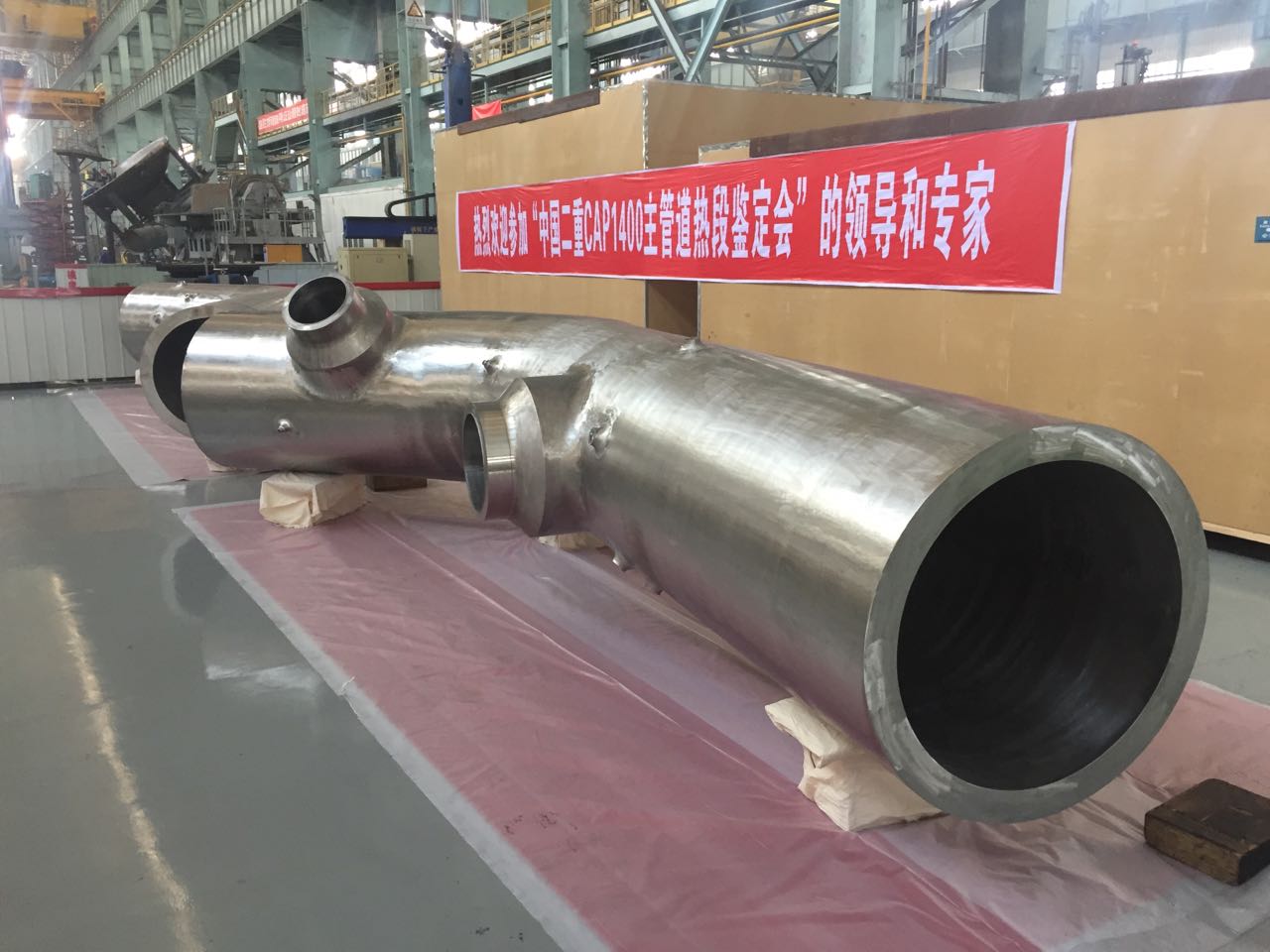

世界上最大规格(外径Φ1088mm、内径Φ900mm)的核岛一回路锻造主管道

——2023年重型机械世界之最科技成果获奖项目专题报道

项目名称:国和一号、华龙一号核电主管道研制关键技术及应用

研制单位: 二重(德阳)重型装备有限公司 www.erzhongheavy.com

首次投运时间:2021年6月

联系人 :陈聪,13708103955,365654942@qq.com

国和一号、华龙一号主管道均采用直管与弯头、管嘴与管道整体锻件结构,是目前世界范围尺寸最大(交货最大外径Φ1100mm)、重量最大(固溶热处理最大重量24吨、交货重量最大17吨)、技术要求最高(椭圆度≤4%、一体化管嘴位置尺寸±1.5mm、晶粒度≥2.0级)、制造难度最大的核岛一回路锻造主管道。

二重装备在完全自主创新的基础上形成系统的锻造主管道制造技术,解决了我国三代核电自主化的“卡脖子”难题,使我国三代核电锻造主管道综合制造技术提高到国际领先水平,解决了国和一号示范工程、华龙一号示范工程、“一带一路”卡拉奇项目对主管道的急需,为我国重大技术装备国产化、三代核电技术的完全自主化和双碳目标做出了重要贡献。

The world 's largest size of forged main pipeline for nuclear island primary circuit ( the outer diameter is 1100 mm and the inner diameter is 900 mm ).

Development and Application of Key Technologies for Nuclear Power Main Piping of Guohe One and HPR1000

Erzhong (Deyang) Heavy Equipment Co.,Ltd. www.erzhongheavy.com

Main pipings of Guohe One and HPR1000 with integral forging structures for straight pipes and elbows,nozzles and pipes,are currently the largest in the world (with the maximum outer diameter Φ 1100mm),the largest in weight (24 tons for solid solution heat treatment,17 tons for delivery), the highest in technical requirements (ovality ≤ 4%, integrated nozzle position size ± 1.5mm, grain size ≥ 2.0),and the most difficult to forged main piping manufacture of nuclear island primary circuit.

On the basis of full independent innovation, Erzhong (Deyang) heavy equipment Co.,Ltd. has formed systematic manufacturing technology for forged main pipings, which has solved " bottle-neck " problem of generation Ⅲ nuclear power localization, raised comprehensive manufacturing technology for forged main piping of generation Ⅲ nuclear power to international leading level, and solved urgent need for main pipings of Guohe one demonstration project, HPR1000 demonstration project, "the Belt and Road" Karachi Project. Significant contributions have been made to localization of major technological equipment, complete autonomy of generation Ⅲ nuclear power technology, and dual carbon goal.